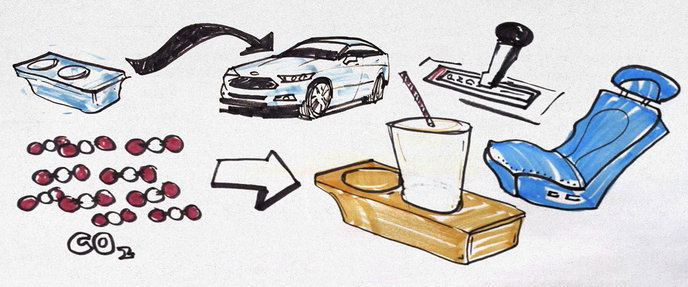

In a quest to use more advanced recycled materials in their vehicles, Ford is now mitigating pollution with a new kind of plastic polymer made from emissions.

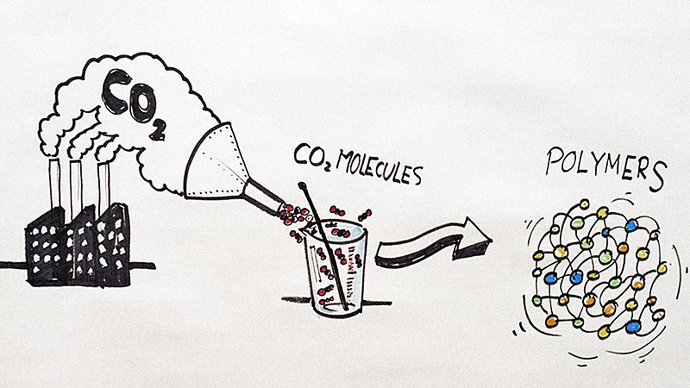

Maybe it’s fitting that one of the first companies to start making products out of carbon pollution is an automaker. For the last four years, Ford has been working with a manufacturer to develop a CO2-based foam, and soon a plastic, that can eventually replace parts made from petroleum.

The shift could reduce petroleum by more than 600 million pounds a year. “There’s 30 pounds of foam in a typical vehicle, and 300 pounds of plastic,” says Debbie Mielewski, Ford’s senior technical leader of sustainability. “So 10% of the vehicle is plastic currently, and that number grows every year as we try to use plastic to replace metal for light-weighting, fuel economy purposes.”

The new foam could be used in headrests, armrests, in door panels, and under carpeting. CO2-based polymers will also be used to make hard plastics for most of the rest of a car.

Ford has been developing alternative materials for the last 15 years; every North American car or truck already uses some soy foam. There’s also coconut fiber used in trunk liners, and recycled clothing and plastic bottles go into carpeting and some fabric.

Each new material faces some initial skepticism. “I think this is about the fourth time that our group has been told there’s no way that this is going to work,” says Mielewski. When the company first started sampling the material, which is made from 50% captured CO2, they couldn’t mix it into a formulation. Now, after years of work with university partners and the manufacturer, they look like ordinary foams, and have passed the company’s screening tests so far.

Though some CO2-based products may eventually come from pollution captured from the air, the current source is power plants. “Right now it’s the smartest thing to take it from a concentrated stream that would otherwise end up being discharged into the environment,” she says. “In order to capture it from the atmosphere would take a lot more energy.”

It will likely take five more years of testing, and scaling up both with suppliers and the polymer manufacturer, Novomer. But in the long term, the company may completely replace petroleum parts in cars. “We have made so much progress in the short period of time we’ve worked in this area, we feel that every single plastic material on a car could be made better for the environment, greener, and have a specific source that is determined to be the best for that product,” she says.

The company is also starting to slowly move away from petroleum as a fuel source: Though Ford only has one electric car now, but by 2020, it plans to add 13 electric cars, hybrids, and plug-in hybrids, but not all will be fully electric.

Source: Fast Company