A new deal has been brokered between industry heavy-weights IKEA and Newlight that is a further indication of the importance of the bio-economy for large consumer brands.

As a sustainable brand, IKEA has consistently positioned itself as a green innovator with a positive impact on both people and planet. In line with this business approach, IKEA takes the lead in the bioeconomy a number of ways, namely, turning waste into resources and developing a strategy for reverse material flows in waste material value chains.

A monumental new biotechnology agreement between IKEA Supply AG and Newlight Technologies will signal another move away from unsustainable virgin fossil-based plastics in line with IKEA’s sustainability goals. The latest agreement will see IKEA invest in a 10 billion pounds production licence with Newlight sustainable materials.

The results for the biotechnology industry will be large-scale, in her last article for Bio-Based World News before heading onto pastures new, Holly Williams explores the implications of this new agreement.

By ensuring key parts of their range are easily recyclable, IKEA has always been committed to taking the lead on reducing overall use of fossil-based materials while increasing the use of renewable and recycled materials within the bioeconomy.

The 10 billion pounds production licence made between IKEA SUPPLY AG @IKEA and Newlight Technologies to purchase AirCarbon @AirCarbon from Newlight production facilities and produce AirCarbon under technology license is a huge step forward for the bioeconomy.

These two industry giants have entered into a supply, collaboration, and technology license agreement that will supply IKEA with the AirCarbon product from Newlight’s commercial-scale production facilities and enable IKEA to produce the AirCarbon thermoplastic sustainable solution.

Under this revolutionary agreement, IKEA will purchase 50% of the AirCarbon material from Newlight’s 23,000 tonne per year plant in the United States. Subsequently, IKEA has the exclusive rights in the home furnishings industry to use Newlight’s exciting carbon capture technology to convert bio-based greenhouse gases, from biogas and later from carbon dioxide, into AirCarbon thermoplastics for use in its range of home furnishing products.

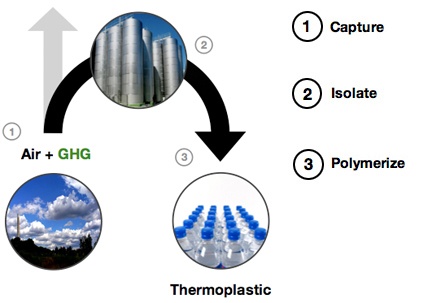

Newslight’s AirCarbon product uses the process of converting air and greenhouse gas into biodegradable plastics, which are proven to out-compete oil-based plastics on price and performance. To learn more about how this process works, take a look at the video below;

IKEA and Newlight will collaborate to choose the best low-cost carbon sources and ensure the development of the technology to use across a range of renewable substrates, with a long-term goal in mind to develop these production capacities to a large-scale 453 KTA or 1 billion pounds per year.

To supply IKEA, the AirCarbon plants are initially intended to use biogas otherwise destined for landfills as their sole carbon feedstock inputs, with expected expansion into other AirCarbon feedstocks over time, such as carbon dioxide alternatives.

Minh Nguyen Hoang, Category Manager of Plastics at IKEA of Sweden summarizes the importance of this new business deal to sustainable initiatives:

“IKEA wants to contribute to a transformational change in the industry and to the development of plastics made from renewable sources. In line with our sustainability goals, we are moving away from virgin fossil based plastic materials in favor of plastic produced from renewable sources such as biogas, sugar wastes, and other renewable carbon sources. We believe our partnership with Newlight has the potential, once fully scaled, to be an important component of our multi-pronged effort to provide IKEA’s customers with affordable plastics products made from renewable resources.”

CEO of Newlight, Mark Herrema also stresses the importance of this move:

“IKEA’s partnership with Newlight marks an important shift in how the world can make materials: from fossil fuels to captured carbon, from consumption to generation, from depletion to restoration. IKEA is a leader in the concept of harnessing its operations to improve the world, and we are proud to be a part of that effort.”

The use of AirCarbon in the IKEA value-chain will assist IKEA’s long-term ambition for all plastic material used in their home furnishing products to consist of renewable or recycled material. The use of AirCarbon in the IKEA product line will start with their home furnishing plastic products, which represents approximately 40% of the total plastic volume used across the IKEA range.

Newlight innovations in focus

“Why can’t we use carbon that would otherwise go into the air as a resource to make materials?”

On average, humans produce more than 660 billion pounds of plastic a year, and the manufacturing process in itself moreover creates three times as much carbon dioxide by weight as actual plastic.

“That’s an insane amount of material,” Newlight Technologies CEO Mark Herrema outlines. “Wouldn’t we be better off using plastic as a conveyor belt for capturing and sequestering carbon emissions instead?”

Newlight Technologies was conceived as a sustainable materials company which uses an unique, innovative carbon capture technology to produce high-performance materials with aim to replace oil-based materials on a market-driven basis.

This dynamic company was co-founded by high-school class-mates Mark Herrema, Co-Founder and CEO; and Kenton Kimmel, Co-Founder and CTO in 2003 (pictured above with Evan Creelman, Newlight COO, showcasing some AirCarbon products).

These Newlight innovators tasked themselves with looking at carbon emissions not simply as a problem, but most importantly, a raw material that could be used to make new materials, materials which could outcompete oil-based materials on price and performance. The idea was simple, sustainable and revolutionary.

These Newlight innovators tasked themselves with looking at carbon emissions not simply as a problem, but most importantly, a raw material that could be used to make new materials, materials which could outcompete oil-based materials on price and performance. The idea was simple, sustainable and revolutionary.

The powerful process addresses two issues: firstly, oil dependency, the process replaces oil with captured carbon emissions. Secondly, climate change, in creating a market-driven carbon capture platform.

Throughout 10 years of challenging research and innovative testing Newlight developed a biotechnological process to produce their AirCarbon material: a family of high-performance polyhydroxyalkanoate (PHA)-based thermoplastic materials made from carbon emissions.

The so called “secret sauce” is a biocatalyst that combines composites of air and methane, and reassembles the carbon, hydrogen and oxygen molecules into a thermoplastic the makers call AirCarbon.

The so called “secret sauce” is a biocatalyst that combines composites of air and methane, and reassembles the carbon, hydrogen and oxygen molecules into a thermoplastic the makers call AirCarbon.

The process is not only more sustainable but, equally, the result is able to match the performance of a range of oil-based plastics while moreover out-competing on price.

The sustainable solutions using greenhouse gas are being applied across value-chains to produce materials used in the production of packaging, furniture, electronics accessories, caps, and a further variety of bio-based products.

Since it’s conception, AirCarbon has been named “Biomaterial of the Year” by the Nova Institute in 2013, “one of the 100 most technologically significant innovations of the year” by R&D Magazine in 2013, and 2014 “Innovation of the Year” by Popular Science before this collosal new licencing with IKEA.

With this collosal new licence in place, we expect big things from this miraculous new sustainable material and its large-scale business investment.

Source: Bio Based News

Women of Green is TURNING UP THE VOLUME of the feminine voice on the planet in order to create the world we know is possible.